How to Choose the Right Load Cell for Your Project

When it comes to measuring force and weight in engineering and industrial applications, load cells play a crucial role. These transducers are designed to convert mechanical force into an electrical signal, enabling accurate measurements in various industries such as manufacturing, aerospace, and automotive. However, with a wide range of load cell types available, it can be challenging to select the right one for your specific project requirements. In this blog, we will explore different types of load cells and provide insights on how to choose the most suitable load cell for your project.

3 Different Types of Load Cells

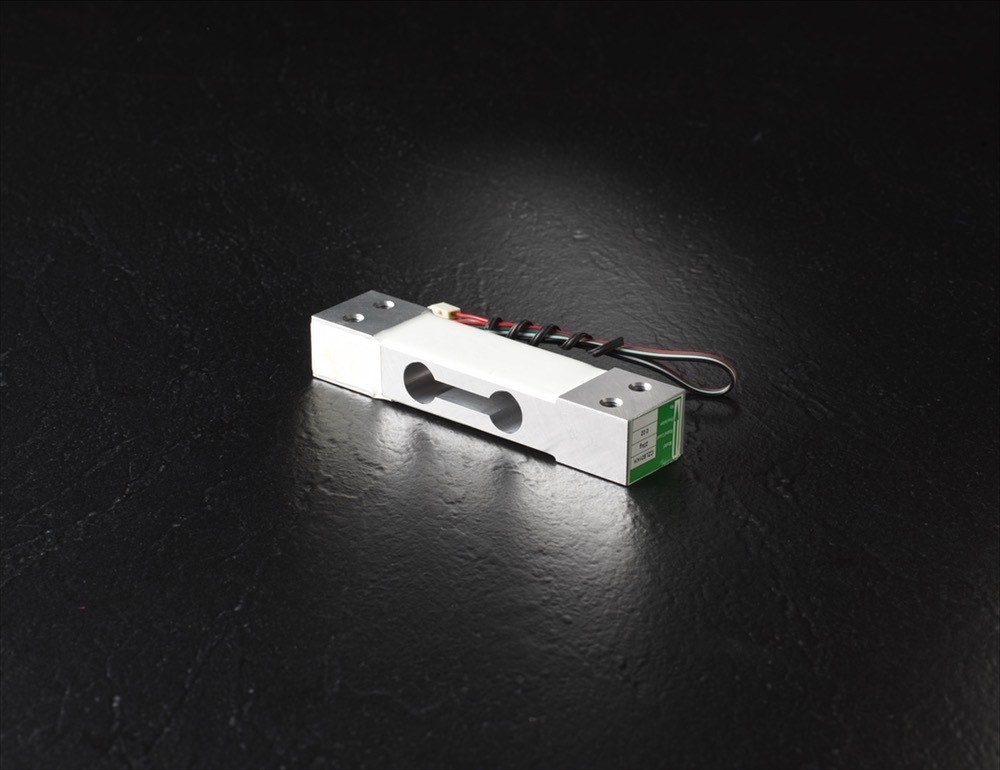

Strain Gauge Load Cells

- Strain gauge load cells are the most common and versatile type available. They work based on the principle of electrical resistance change under applied strain. This type of load cell is suitable for general-purpose applications and can be found in compression, tension, and bending load cell configurations. They offer high accuracy, and cost-effectiveness which of course are two key factors in decision-making. If these are the choice for you, then get in touch today to get started.

Hydraulic Load Cells

- Hydraulic load cells utilize the concept of fluid pressure to measure force. They are often chosen for heavy-duty applications that involve high-capacity weighing or testing. Hydraulic load cells are resistant to shock and overload, making them suitable for harsh environments. However, they require additional accessories such as a hydraulic power unit and fluid-filled tubing.

Pneumatic Load Cells

- Similar to hydraulic load cells, pneumatic load cells operate on the principle of fluid pressure. However, they use compressed air instead of liquid. Pneumatic load cells offer advantages such as fast response times, high accuracy, and intrinsic safety, making them suitable for applications involving explosive or hazardous environments. They are commonly used in industries such as oil and gas, chemical, and mining.

How to Choose the Right Load Cell for Your Project

Consider the Load Capacity

Identify the maximum load capacity required for your project. Load cells come in various capacities, ranging from a few grams to several thousand tons. Select a load cell that can handle your anticipated load range, ensuring accuracy and reliability.

Determine the Environmental Conditions

Evaluate the environmental conditions in which the load cell will operate. Consider factors such as temperature, humidity, vibration, and potential exposure to corrosive substances. Choose a load cell that is specifically designed to withstand these conditions to ensure long-term performance.

Understand the Accuracy Requirements

Assess the level of accuracy needed for your application. Different load cells offer varying degrees of accuracy, typically expressed as a percentage of full-scale output. Determine whether your project requires high precision or if a lower accuracy range is acceptable. This consideration will help you select the appropriate load cell.

Evaluate Physical Constraints

Take into account any physical limitations or constraints of your project. Consider factors such as size, shape, and mounting options of the load cell. Ensure that the chosen load cell can be easily integrated into your system and meets the spatial requirements of your project.

Load cells are used in various industries and applications, including:

- Manufacturing and Industrial Processes: They are essential for material testing, quality control, assembly line monitoring, and process automation.

- Aerospace and Aviation: Load cells ensure weight and balance calculations, structural testing, and force distribution analysis in aircraft.

- Automotive Engineering: They contribute to vehicle weight distribution, suspension system analysis, brake and tire testing, and crash tests.

- Construction and Civil Engineering: Load cells are used for load testing structures like bridges and buildings, as well as geotechnical engineering.

- Energy and Power Generation: They measure forces in power generation equipment and aid in renewable energy applications.

- Medical and Healthcare: Load cells assist in patient weighing scales, rehabilitation equipment, and prosthetics.

- Research and Development: Load cells support experiments and data collection for analysis and innovation.

- Food Processing and Packaging: They ensure accurate weighing and portioning in the food industry.

Selecting the right load cell is crucial for obtaining accurate and reliable force measurements in your project.

By understanding the different types of load cells available and considering factors such as load capacity, environmental conditions, accuracy requirements, and physical constraints, you can make an informed decision. Remember to consult with load cell manufacturers or experts who can provide guidance specific to your application. Investing time and effort into choosing the right load cell will ultimately lead to improved performance and successful project outcomes.

TyTek Industries are highly experienced in supplying high-volume strain gauge load cells, so get in touch with us today to kickstart your manufacturing project!

Follow us on our social media to stay up to date with the TyTek HQ.